New report’s primary focus is on codigestion strategies that water resource recovery facilities can develop to create value, and to manage the associated financial risks.

Carol Adaire Jones

BioCycle November/December 2019

Editor’s Note: This article is excerpted from a soon-to-be-published report for the Water Research Foundation on business strategies for codigestion of food waste at wastewater resource recovery facilities (WRRFs). It summarizes the report’s key findings about WRRF codigestion experiences and successful business strategies, including solutions to impediments and risks that have slowed the adoption of codigestion.

The City of Dubuque utilized an opportunity to include investment in AD and energy generation as part of a very large-scale capital improvement project to update its WWTP. Photo courtesy of City of Dubuque, Iowa

A new report — “Food Waste Codigestion at Wastewater Resource Recovery Facilities: Business Case Analysis” — represents the last logical link in a series of topics covered in the Water Environment and Reuse Foundation (now the Water Research Foundation (WRF)) program of research exploring the technology and economics of implementing codigestion. Other research in the series examined strategies to address operational and regulatory risks (Van Horne et al. 2017, Appleton et al. 2017).

These studies were motivated by the unrealized potential for codigestion in the wastewater sector. Though codigestion can provide financial benefits to WRRFs, as well as a broad range of environmental and community benefits, fewer than 1 in 10 of the 14,000 wastewater treatment plants use anaerobic digestion (AD) to process wastewater solids, and fewer than 1 in 10 of those codigest food waste. The literature has identified various financial, operational, regulatory, stakeholder/political, and organizational risks and impediments to adoption of codigestion and energy generation projects, which are outside core wastewater treatment services.

The new report’s primary focus is on strategies WRRFs can develop to create value, and to manage the associated financial risks. These risks may include issues of inadequate, and/or uncertain, financial benefit streams (e.g., due to lack of reliability in quantity, quality and/or price of feedstock supply; or lack of reliability in quantity produced and/or sales price of WRRF end-products); and uncertainty about access to capital, and related challenges in getting approval of investment projects, financing, and rate increases. The report is concerned with other sets of impediments and risks (studied in prior reports in the WRF series) to the extent that they affect the economics or access to capital.

Our initial hypothesis was that we could identify alternative business models for codigestion at wastewater treatment plants from which utilities could select to suit their context. However, we quickly concluded there is no straightforward menu of options. Rather each utility needs to tailor its business strategy to its mission, resources, and scale, as well as its external market and policy environments.

The report offers general principles and case study examples of how to create value and manage risks in a food waste codigestion program, plus a framework for utility self-assessment to analyze the opportunities and the business case for codigestion. Six major case studies, plus 25 thumbnail sketches, are reported, which together represent the full range of WRRFs based on WRRF characteristics (size, region), policy and market environments, and strategic choices in food waste feedstocks, energy uses, biosolids uses, contracting and financing options. The report also provides examples of WRRFs that decided against adopting codigestion, or that have suspended or cutback programs in place. To inform our analysis, structured interviews were conducted with more than 65 organizations, including wastewater utilities, and representatives from the solid waste, energy, technology, project development, and government sectors.

WRRF Codigestion Experiences

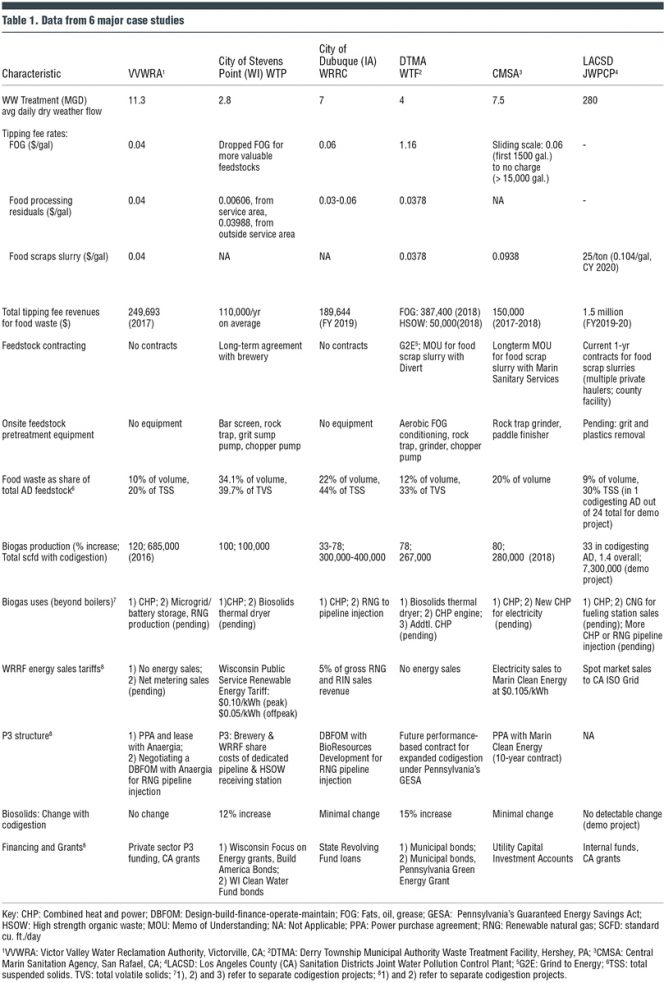

The report summarizes key takeaways from our study of over 30 WRRFs. Table 1 summarizes findings for the six major case studies in the report.

Financial Drivers: Most frequently mentioned by WRRFs were rising energy costs, and financial support programs to promote greenhouse gas mitigation, renewable energy, and food scrap diversion. Some also cited their opportunity to add investments to support codigestion as part of large facility upgrade investment projects, which allowed them to scale planned AD, energy, and/or biosolids management investments to accommodate codigestion.

For example, the City of Dubuque, Iowa, capitalized on an opportunity to include investment in AD and energy generation as part of a very large-scale investment project to upgrade the outdated and inefficient wastewater plant. Incorporating resource recovery and transforming the plant into a Water and Resource Recovery Center addressed the City’s sustainability goals.

Operational Drivers: These included underutilized AD or energy infrastructure, more stringent requirements for biosolids management, and the need to divert growing quantities of pretreatment program wastes to AD in order to preserve wastewater treatment capacity and the economic development potential to attract new “wet” businesses to the area. For example, Stevens Point, Wisconsin, considered codigestion to be essential to process the dramatic increase in brewery pretreatment wastewaters that resulted from the escalating expansion of its local brewery.

Food waste prior to preprocessing into a slurry at the Los Angeles County Sanitation Districts’ Puente Hills MRF. Photo courtesy of Los Angeles County Sanitation Districts

Environmental and Community Drivers: Examples include: providing a service to FOG (fats, oils, grease), food processing and food scrap waste generators (particularly ones from their service area) that are facing more stringent regulatory requirements; supporting economic development; and contributing to community goals for sustainability, renewable energy, greenhouse gas (GHG) reduction, and food scrap diversion. The Los Angeles County Sanitation Districts (LACSD) is a joint solid waste-wastewater agency. Its codigestion initiative is motivated in part to serve the needs of its solid waste stakeholders, now required to comply with a statewide food scrap recycling mandate. LACSD created its own food scrap slurrying facility at its Puente Hills Material Recovery Facility, so that small to medium-sized hauling companies could have an affordable processing option that would allow them to remain competitive (see “Sanitation Districts Gears Up For Food Waste Codigestion”).

Decision Criteria For Investments: Many codigestion projects were required to meet return on investment (ROI) or payback period tests, though the thresholds for approval varied widely. For non-core mission projects, LACSD uses 5 to 10 years as a maximum payback target, whereas Stevens Point requires a robust ROI on a 20-year cash flow analysis. WRRFs also placed different requirements on these projects in non-core business lines, including maintaining or improving water quality, no detrimental impact on facility operations, and no impact on water rates.

The Victor Valley Water Reclamation Authority (digesters shown) has used public-private partnerships for both of its energy development projects.

Project Scope And Costs: Successful codigestion programs are typically implemented over time in a series of projects or phases. The scale of investment for the initial project varies tremendously across WRRFs, depending upon the facilities currently available, the type and quality of incoming feedstock supply, and the stage of commitment to codigestion. For example, the Victor Valley WRA (VVWRA) spent $10,000 to convert an existing tank to a FOG receiving station, whereas Central Marin Sanitation Agency in San Rafael, CA, spent $2 million on a new organics receiving station, which includes a 300,000-gallon tank, mixing pumps, rock trap grinder, paddle finisher and odor control system (see “Codigestion At Water Resource Recovery Facilities”).

Among energy projects, the costs of renewable natural gas (RNG) pipeline injection vary widely depending upon interconnection requirements — which vary across states and utilities — and pipeline proximity and the related factors that affect the cost of pipeline access.

Source separated food waste collected by Marin Sanitary Service is preprocessed on a sorting line and in a vertical grinder (1), then hauled to the Central Marin Sanitation Agency’s WRRF (2) where it is unloaded into a receiving tank (3). Anaerobic digesters at CMSA (4).

Cost Savings and Revenues: The sources of financial gain most frequently cited by WRRFs included: tip fee revenues (which can contribute revenue streams to support major AD upgrades, as well as receiving station investments), energy cost savings and/or revenue, savings in wastewater aeration costs by diverting liquid wastes from the headworks to the digester, and savings in biosolids management costs by supporting thermal dryers to create Class A EQ biosolids. Also cited were financial incentive programs providing grants or green payments.

Biogas and Biosolids Production: Biogas production increased substantially from the addition of codigestion substrates, with rates of increase depending upon share of high strength organic wastes (HSOW) in digester feedstocks, and share of total digesters involved in codigestion. Plant managers for four out of the six major case studies reported biosolids did not increase with codigestion.

Resource Recovery Product Lines: As innovative arrangements are being introduced to supply food scrap slurries, more WRRFs are slowly beginning to tap into the underutilized potential of food scraps as AD feedstock. When the relative values of energy subsidy programs shifted more in favor of production of vehicle fuel a few years ago, many more WRRFs began evaluating projects to produce RNG for use as vehicle fuel or pipeline injection (typically for vehicle fuel) as an alternative, or as a complement, to producing renewable heat and power. Current uncertainties in the federal Renewable Fuel Standards’ RIN prices due to Administration policies have engendered a wait and see attitude for WRRFs planning energy projects a few years down the road. (For details, see “Biogas To RNG Projects: What, Why And How” and “Market Outlook For Low Carbon Fuels”).

Evolving Trends: Though WRRFs have been reluctant, and in some cases prohibited by charter, to engage in Public-Private-Partnerships (P3) in the past, they are moving into performance-based contracting for new projects outside their core area of expertise, notably energy projects, and especially RNG projects. Benefits of entering into a P3 cited by WRRFs include accessing expertise not available in-house, shifting risks, and, infrequently, accessing private financing to circumvent public capital constraints and potentially long and politicized approval processes.

For example, the Derry Township (PA) Municipal Authority (DTMA) is developing a performance based contract with Energy Services Group for expansion of AD and feedstock supplies. Its contract will provide guarantees for tip fee revenues. VVWRA has used P3s for both of its energy development projects, and is the one example in the report of using P3s for financing as well as construction and operations.

Codigestion No-Goes

Among WRRFs that evaluated codigestion, the primary reason offered for not going forward is the lack of sufficient economic returns. Contributing factors cited include uncertain or low feedstock supply and revenues, low energy prices (and, as a result, low energy savings), scale too small to attain economies of scale, and lack of incentive programs to provide financial support. Nonfinancial reasons offered for no-go decisions include NIMBY (not in my backyard) concerns and changes in political leadership, with resulting changes in priorities.

Plants have suspended codigestion due to changes in feedstock or energy markets that reduced revenues or savings, problems with feedstock quality or availability, and unanticipated requirements to invest in additional equipment. Plants have cutback codigestion due to the loss of a major supplier(s) (and no program to develop feedstock supplies). Others cite the loss of capacity to recycle biogas or biosolids, and the lack of capacity to make needed investments for additional capacity, at least in the short run.

DTMA stopped accepting food scrap slurries after losing part of its capacity to manage biosolids when its thermal dryer was taken out by a flood, but continues to accept FOG and food processing residuals. The dryer’s replacement is in the capital budget schedule for approximately 5 years in the future.

Successful Business Strategies — Essential Elements

The business challenge WRRFs face is to create a balanced system across all the elements required to recycle food waste, recover products and create value. These elements include coordinating plant AD capacity, feedstock supplies and feedstock receiving station capacity — with plant capacity to recycle the biogas and biosolids into valuable products. For each WRRF, the specifics of a successful business strategy for codigestion vary depending upon the policy and market environment in the region, as well as utility long-term strategic goals, organizational culture, and resources.

To create a successful codigestion program, a utility needs to have certain elements in place:

• Codigestion champion in the utility or municipal government.

• Enough site space for vehicles to deliver feedstocks and for other equipment needs

• Business mindset to resource recovery

• Visionary utility board or municipal decision-makers who will support projects beyond the core wastewater mission that make economic sense to ratepayers

• Location with access to a sufficient supply of feedstock at a good price

Key elements of a successful business strategy include the following:

• The business strategy ensures codigestion operations will not compromise plant compliance with its environmental permits, and the WRRF’s responsibilities for public health and environmental quality, which are central to its mission.

• The business strategy employs a life cycle perspective, taking into account revenues and costs from the time of initial investments through repair and replacement investments. The full benefits of codigestion typically will not accrue until the WRRF has achieved a mature program with a balanced set of AD, energy generation, and biosolids management capacity. Identifying the full costs necessitates delineating the capital requirements for maintaining and upgrading the assets that support codigestion.

• The business strategy leverages available drivers in sync with the WRRF mission. Drivers include market-based opportunities to generate revenues and cost savings, policies regulating wastes, policies providing green payments to support investments in sustainability, as well as utility and community commitments to environmental and community services.

• The business strategy incorporates elements to mitigate financial risks. Options include diversifying sources and product outlets, establishing long-term contracts for purchasing feedstocks or selling products, building in equipment redundancies to allow for scheduled or unscheduled maintenance, and using public-private partnerships/contracts to share construction and operating risks with the private sector.

• A business case for investment capital that can be successful is to highlight the financial value codigestion can contribute to larger investment projects required for regulatory compliance or for regularly scheduled maintenance and upgrades in the utility asset management plan. Further important environmental and community goals to highlight include providing a service to FOG, food processing and food scrap waste generators (particularly ones from their service area) that are facing more stringent regulatory requirements, and contributing to community goals for sustainability, renewable energy, GHG reduction, and food scrap diversion.

As a WRRF learns from experience over time and is able to improve economic performance from resource recovery, the strategic questions evolve. For example, for AD capacity, the focus evolves from identifying excess capacity, to rationing capacity to the highest value sources, and finally to examining the potential for codigestion to support expansion in AD capacity. For energy, the focus evolves from achieving onsite energy neutrality, to breaking down barriers to accessing the power grid, to exploring the potential for supplying RNG to the market.

Conclusion

Codigestion at WRRFs can be successful where there is a fit with the organization’s culture, support from the utility decision-makers for projects outside of the core mission area, and market and policy opportunities to create economic value. It is important to recognize that codigestion does not fit in all circumstances. In some contexts, the business case analysis will indicate that the best option, under the current understanding of life cycle potential, is to not move forward at this time. It may also provide insights for a path toward a future successful codigestion program.

Carol Adaire Jones, an environmental economist, is a Visiting Scholar at the Environmental Law Institute (ELI) and co-leads its Food Waste Initiative. She was the Principal Investigator on the WRF study. Coauthors were Co-Principal Investigators Craig Coker (Coker Composting & Consulting) and Ken Kirk (former Executive Director of National Association of Clean Water Agencies); and Lovinia Reynolds (ELI).