Top: Manure anaerobic digester facility, EnTech Solutions in partnership with Northern Biogas, Middleton, WI. Photo excerpted with permission from Wisconsin Biogas and Feedstock Survey Final Report.

Nora Goldstein

Measures taken to improve cost-effectiveness of operations and maintenance. Graphic excerpted with permission from Wisconsin Biogas and Feedstock Survey Final Report.

Wisconsin’s Office of Energy Innovation (OEI) teamed up with the University of Wisconsin-Stevens Point to assess and document the current status of the state’s biogas industries, evaluate impacts of relevant policies and incentives, and learn about current challenges that the biogas facilities face. The findings from this study — released in May 2021 — will be used to address barriers and challenges and promote biogas production and use in Wisconsin.

The study focuses on all biogas facilities in Wisconsin. A survey was sent to 318 existing (operational and non-operational) biogas facilities, and about 300 potential industries that might consider biodigesters for their facilities. Responses were received from 82 facilities and form the basis for the Wisconsin Biogas and Feedstock Survey Final Report. The study was conducted between October 2020 and March 2021. The new report serves as a follow-up to a previous Biogas Survey Report conducted by the Public Service Commission of Wisconsin, and OEI in 2016. It will be used to support Wisconsin’s Clean Energy Plan (to be released in 2021), an initiative resulting from the Governor’s Task Force on Climate Change Report.

This article provides an overview of the survey findings. A more detailed analysis will be provided by the report’s authors in an upcoming BioCycle CONNECT article.

Food waste-to-energy biodigester facility, Forest County Potawatomi Community Renewable Generation, LLC, Milwaukee, WI. Photo excerpted with permission from Wisconsin Biogas and Feedstock Survey Final Report.

Biogas Facilities In Wisconsin

Based on the study results, the majority of the biodigesters in Wisconsin are installed at municipal wastewater treatment facilities (WWTFs), followed by dairy and agriculture sector-based biodigesters. Digesters at food processing and industrial waste operations and landfills with biogas systems comprise the remainder of the installations. Most of these facilities have been built within the last 50 years (1970 to 2020) with a large number added in the last decade (2010-2020). A small percentage of installed biodigesters are currently not operational. Odor control, enhancing renewable energy production, and added facility income are the primary motivators for installing digester systems.

On average, biodigesters cost $3 million or more to install, although small-scale units can be installed for less than $100,000. A large number of facilities were built without any grant support. Among the facilities awarded grants, most received 10% to 30% funding to offset installation costs.

On average, most of the biodigester facilities have volume capacity of 2 million gallons to handle the slurry. Average biodigesters in Wisconsin have 42,000 cubic feet of gas storage capacity and daily rated gas production volume capacity of 300,000 cubic feet.

Survey Finding Highlights

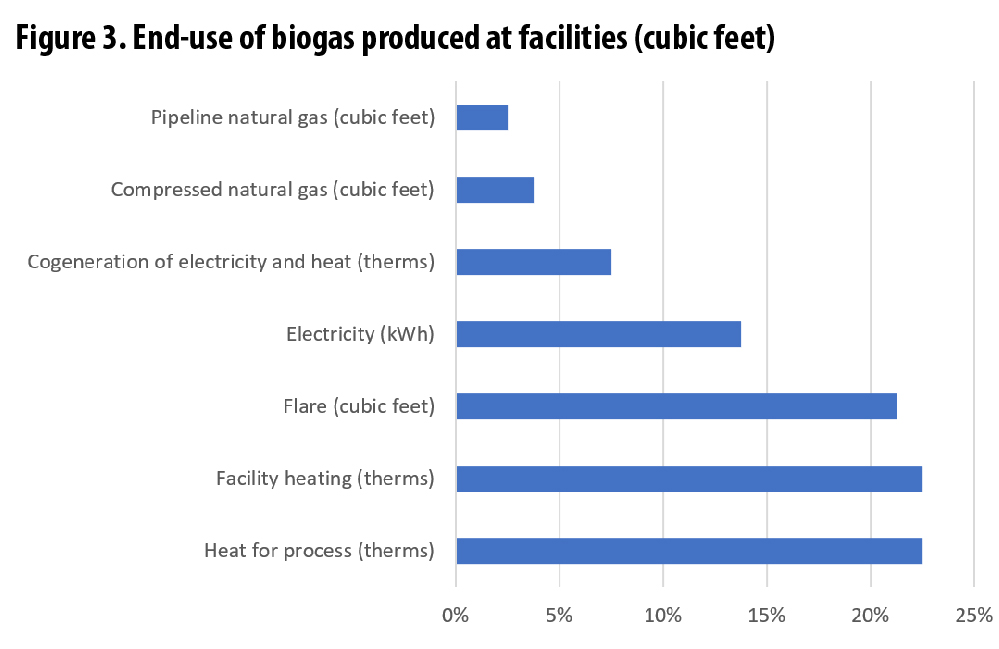

- Sources and Use of Feedstock: Figure 1 shows the primary sources of digester feedstocks in Wisconsin. Municipal wastewater is the largest source; manure from dairies is the second. Figure 2 highlights supplemental feedstock sources accepted at biodigesters. Materials include feedstocks from food processing industries, restaurants, and breweries. Most tend to come from within a 20 miles radius of the biodigester facilities although some are sourced from a distance of 50 miles or more. Top challenges cited for feedstock acquisition and use include storage, inconsistent timing and frequency of feedstock supply, and contaminants in feedstock.

- Biodigester Operations And Maintenance: Most biodigesters in Wisconsin employ 1 to 5 staff to support their operation and maintenance (O&M). Reported annual O&M costs vary — half of the respondents cited costs below $100,000 while others reported costs of $150,000 or more. Only a few biodigester facilities currently have infrastructure to inject refined biogas (renewable natural gas, or RNG) into the natural gas pipeline. The major O&M challenges include biogas cleaning for onsite use, generator malfunction, foaming, maintaining quality and quantity of the biogas, and overall cost of operations.

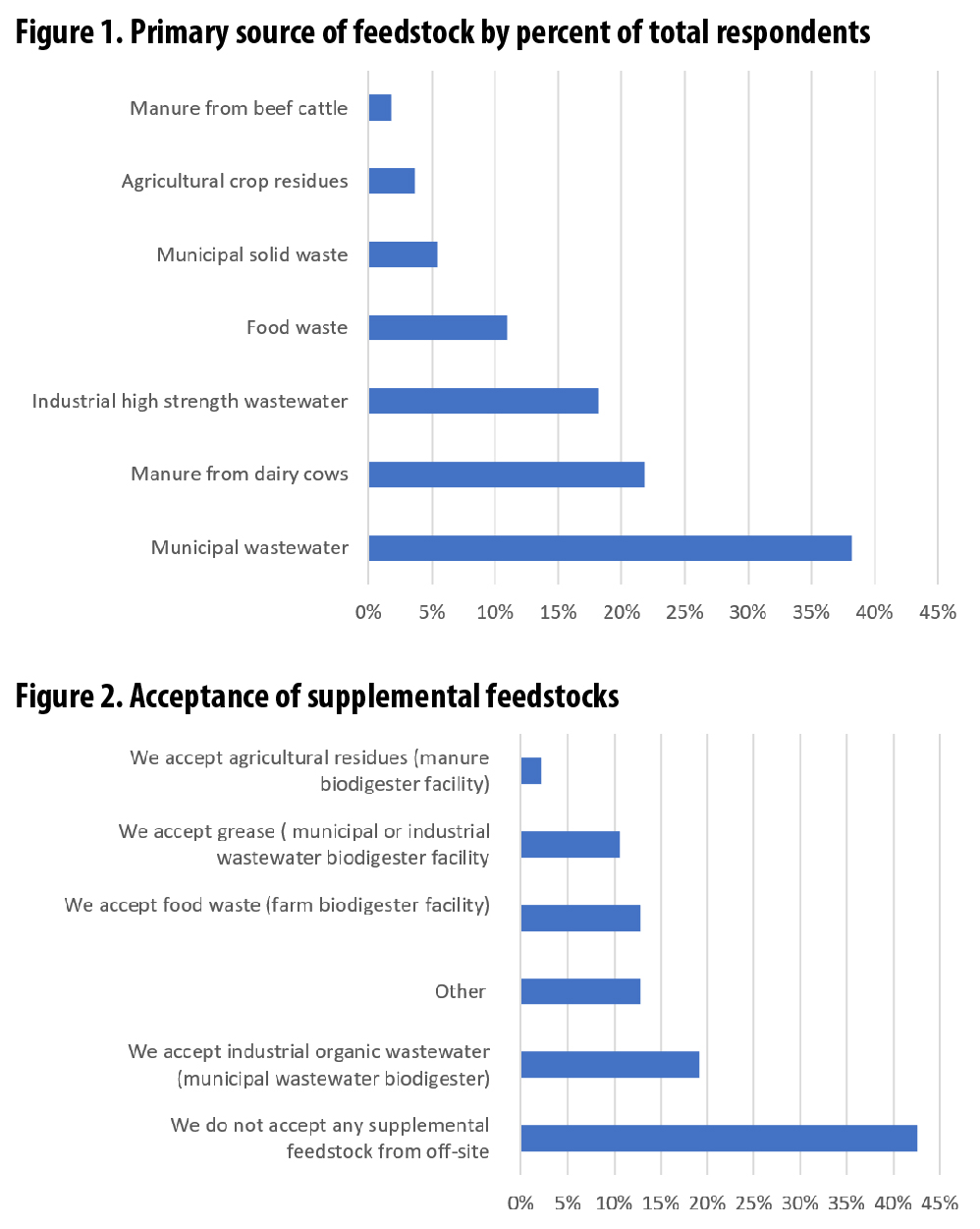

- Production and End Use: Figure 3 summarizes the end uses of biogas at facilities. Utilizing biogas as digester process heat and for heating facilities are the most common practices. Many facilities produce electricity using the biogas while a small percentage have cogeneration equipment to produce heat and electricity together. Depending on the size and capacity of the digesters, daily production of biogas varies from 25,000 cubic feet to more than 500,000 cubic feet. The majority of facilities generate co-products such as fertilizers, composts, and bedding for livestock. Nutrient management plans are used to comply with regulations and environmental issues.

- Power Purchasing: A very small percentage of Wisconsin’s biodigester facilities have power purchase agreements with their utilities and most of those agreements are set to expire by 2023. A majority of the facilities that sell electricity receive less than $0.09/kWh; most prefer a higher rate of electricity in order to break-even or start making a profit from their biogas operations. Many operators support having a state-level mandate on their electricity rate.

- Policies and Challenges: Major challenges in adopting a biodigester include permitting, waste contracts, nutrient management concerns and regulations, generator commissioning, and grant writing. Survey respondents requested more grant funding opportunities to offset capital cost of biodigester installation, and supportive policies and incentives to promote the biogas industry in Wisconsin. A majority of the facilities suggest developing policies that mandate food diversion from landfills and a national renewable fuel standard policy to assist biogas industries.

- Lessons Learned and Recommendations: When considering building another biodigester, many facilities would like to make changes that include: better handling, mixing, separating and scrubbing systems, adopting better heating system, changing generator capacity, having ability to better manage nutrients and substrates, and having RNG injection capability.

Recommendations cited by survey respondents include: Helping secure viable project financing and facilitate more investment options to stimulate the growth of biogas facilities; Removing barriers to selling electricity or biogas to utilities or interstate producers/suppliers that may include a better net metering policy and facilitating more options for injecting into a natural gas pipeline; Establishing favorable environmental regulatory compliance standards; and Strengthening organizational partnerships and cross-sector collaboration to enhance education and outreach, information sharing, and public awareness.