Van Calvez

Cannabis is now legal for at least some medical uses in 48 states and the District of Columbia; 15 of those states have approved it for recreational purposes. Medicinal use of cannabis has been legalized in Canada since 2001. In the United States, the regulatory requirements for composting cannabis residuals are rapidly changing and sometimes make it difficult to practically compost them. These regulatory requirements will hopefully stabilize over time.

This article takes a closer look at the feedstocks generated by cannabis growers and processors and examines how they can be effectively composted. The emphasis is on hot, aerobic, thermophilic composting of the cannabis residuals versus anaerobic digestion or slower composting processes (such as vermiculture), although these methods are certainly feasible as well. Additionally, the focus is on the composting of cannabis/marijuana cultivated for medical or recreational use (not industrial hemp production). Part I discusses the types of cannabis waste feedstocks generated, and analyzes the C:N ratios and other characteristics. Part II looks at size reduction and compost recipes.

Three main types of cannabis residuals are often available for composting:

- Grow Residuals: Generated by the growing and harvesting of the cannabis plant — including leaves, stalks, roots/soil, seedlings — that are not used to make a sellable product

- Process Residuals: Result from the processing/extraction of cannabis into saleable products

- Product Residuals: Returned, recalled, rejected products from the cannabis industry, including lozenges, oil, topicals, edibles, gummi bears, etc.

Grow Residuals

By volume of feedstocks, the major types of cannabis grow residuals include:

- Fan leaves: These easily recognized leaves of a cannabis plant are actually low in cannabinoids and therefore not a source of sellable product. Since cannabis is predominantly a leafy, green plant, fan leaves are often the predominant grow residual by volume.

- Seeds/seedlings: This would also include rejected, immature plants.

- Stem (stalks): Fibrous support structures of the cannabis plant.

- Growing media/soil/roots: Everything below the level of the soil.

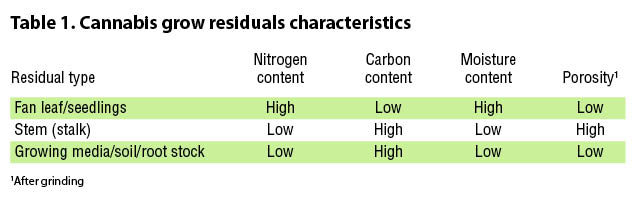

Table 1 outlines the nitrogen, carbon, moisture and porosity characteristics of each grow residual. A cannabis plant is predominately a leafy green. In composting terms, the fan leaves have a relatively high nitrogen content and a relatively low carbon content. This equates to a carbon to nitrogen (C:N) ratio that is relatively low (e.g., about 15-20:1).

An overall recommended starting C:N ratio for hot composting is in the realm of 25:1 or 30:1, therefore additional carbon would be beneficial to facilitate an aerobic composting process. In addition, those fan leaves (especially when shredded) will not hold a tremendous amount of air space in a compost pile (similar to grass clippings). Therefore, a carbon-rich bulking agent may be warranted to increase porosity in the compost pile.

The cannabis plant also provides fibrous stalks (called “stem” in the business) that, once shredded, can provide much needed carbon and porosity for a compost process. However, these tend to be a smaller constituent than the leaves by volume, especially once shredded. The remaining grow residual feedstocks include root stock and growing media such as coir, peat moss, and various types of fertilizers, including compost. These are all fine contributors to a compost recipe and represent a good source of carbon and porosity.

The growing media also often includes inorganics such as soil, vermiculite and rock wool. These constituents do not biologically decompose and therefore do not directly contribute to a biological composting process but may contribute (or inhibit) porosity depending upon density, moisture content and particle size.

If there are large proportions of these inorganic feedstocks, it may be preferable to add these at the end of the thermophilic composting stage. However, this may not be an option from a regulatory standpoint. Small proportions of inorganics in the compost mix will likely not interfere with the composting process.

The growing media may also include compostable or non-compostable grow plugs and other plastics. Compostable plastics can presumably be composted, assuming a sufficiently large, hot composting mass is available. The non-compostable plastics should be hand picked before composting or screened from the final product.

Cannabis Processing Residuals

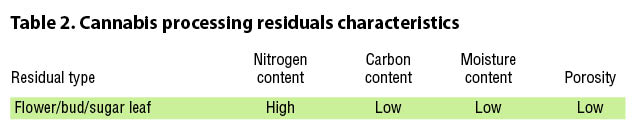

Processors take the commercially valuable parts of the cannabis plant and process them into sellable products, including parts of the female cannabis flowers and the sugar leaf trim. Therefore, process residuals include sugar leaf residuals and flower/bud residuals. Often, valuable oils are extracted from the flower/bud leaving a residual that is crumbly or dusty and low in moisture content, though still with significant nitrogen content. Table 2 highlights characteristics of these materials.

Processing cannabis sometimes involves use of solvents to extract the product. Residuals contaminated with solvents should not be added to a compost recipe. These are typically treated as hazardous wastes and disposed of separately.

Processing cannabis sometimes involves use of solvents to extract the product. Residuals contaminated with solvents should not be added to a compost recipe. These are typically treated as hazardous wastes and disposed of separately.

Cannabis Product Rejects/Residuals

Effective composting of cannabis-related products depends largely on the type of rejected cannabis product that needs to be composted. For instance, cannabis-infused oils would need to be absorbed by some type of media. This could be the flower/bud residual mentioned above if available. Or it could be something with similar characteristics, such as sawdust.

Rejected cannabis products will presumably be a smaller constituent by volume and weight to a larger composting process. In addition, these products will typically provide high nutrient (nitrogen) content but lower carbon, lower moisture, and low porosity. In this way, rejected cannabis products will typically be similar to cannabis processing waste in terms of compost recipe needs.

The 50-50 Rule

Many state regulations for the disposal of cannabis waste require the cannabis to be mixed at least 50%:50% by volume with non-cannabis waste in order to render the cannabis waste unusable. While this rule requires composters to source non-cannabis feedstocks, these materials can also help produce a balanced recipe for hot composting.

Sources of carbon-rich bulking agent to comply with this rule include wood chips, leaves, chopped straw, horse manure and bedding, and shredded cardboard. Sources of nitrogen-rich feedstocks include shredded landscape residuals, grass clippings, and food scraps.

In Part II of this article, we will examine the recipes and methods recommended for composting these feedstocks.

Van Calvez, a Composting Systems Designer and Engineer with Green Mountain Technologies (GMT), specializes in in-vessel composting systems for organizations and communities.