Researchers in Italy examined fate of nitrogenous compounds during composting to meet EU nitrate limit of 152 lbs/acre.

Alessandro Chiumenti and Craig Coker

BioCycle July 2017

Figure 1. Horizontal reactor trough and traveling bridge at the Bosco Chiesanuova swine farmWhile much of the discussion about nutrient-rich runoff degradation of water quality is focused on phosphorus (see “Phosphorus and Compost Use Dynamics,” December 2016), there are significant areas in the U.S. where nitrate contamination of groundwater remains an issue. These nutrient-sensitive areas may pose some constraints to the direct land application of animal manures, sewage sludges and digestates from anaerobic digestion (AD) plants.

A team of researchers at the University of Udine in Italy has examined the fate of nitrogenous compounds as part of an investigation into means of treating animal manures and digestates to meet the European Union’s 1991 Nitrates Directive, which limits land application of nitrogen nutrients to 170 kg/hectare/year (about 152 lbs/acre) in nitrate-vulnerable areas. This work was carried out at full-scale in several facilities, including four composting plants treating manure and digestate in liquid phase. In particular, tests were performed at a 1,000-head swine farm in Bosco Chiesanuova in northern Italy. The composting system at the farm is designed to handle 8,000 cubic meters (2.1 million gallons) per year of liquid swine manure.

The composting system, the CLF Modil (Biogest Service, Italy), is based on the agitated bed technology with significant modifications. The composting reactor at Bosco Chiesanuova is a horizontal trough, 252 ft. (77 m) long, 33 ft. (10 m) wide and 4.3 ft. (1.3 m) deep (Figure 1). (Minimum width of the trough is 20 ft. to a maximum 65 ft., with length up to 393 ft. for a single unit, treating roughly 1,300 to 18,500 gallons/day.) In order to process the input, liquid absorbents are used, such as straw, wood chips, sawdust, corn stalks and similar carbon-rich materials. Eventually the solid fraction from liquid/solid separation can be utilized. In this research project, only straw and sawdust were used as amendment.

The concrete walls of the trough support and guide the traveling agitation and aeration bridge, which spreads the liquid manure over the absorbent bed. Five rotating screws mounted on the bridge turn the material; air is introduced through aeration holes in the screws (Figure 2). Air is supplied at a rate of 117.7 ft.m3/minute (200 m3 /hour). For each operation (liquid manure spreading and mix turning), the bridge travels lengthwise at a speed of 17.7 ft./minute (5.4 m) and the screws move across the bridge at a speed of 1.1 ft./min. (0.35 m).

Typically a composting cycle lasts for 17 weeks, with manure or digestate added daily until the last two weeks of the process. Temporary storage of liquid feedstocks in a tank is not strictly necessary but in some cases is practical, especially during maintenance or between cycles.

Monitoring And Data Analysis

Several composting cycles were comprehensively monitored during the study; data in this article is from only one monitored cycle, which lasted 200 days (28.5 weeks). At start-up, the trough was filled with sawdust and straw to a depth of 4 ft. (1.2 m). Liquid swine manure (1.1% total solids) was added daily at the rate of 8,718 gallons/day (33 m3/day). Spreading the manure required 1 hour/day, turning required 5 hours/day and the mix composted in an undisturbed static pile with no aeration for the remaining 18 hours/day. Installed power is approximately 12 kW, thus energy consumption was 72 kWh/day (2.18 kWh/m3 of input). Total loading on the cycle discussed in this article was 7,082 tons (6,425 metric tons (mt)) of manure, 55 tons (50 mt) of straw, and 330 tons (300 mt) of sawdust. Output from this cycle was 540 tons (490 mt) of finished compost, with a mass loss of 92.8 percent, of which 90.1 percent was evaporated water and 2.7 percent was loss of solids.

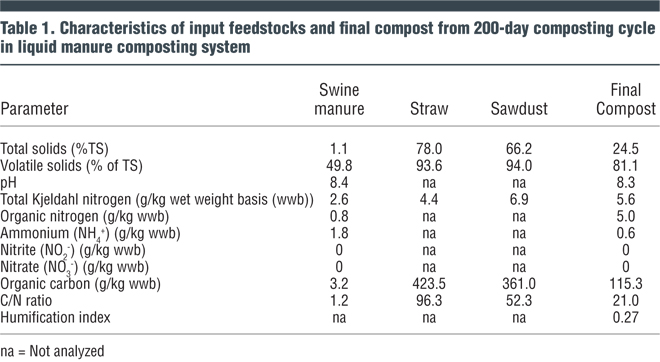

Characteristics of the input feedstocks and the compost output are shown in Table 1. Although the final compost product had a C:N ratio of 21:0, suggesting additional maturation would be warranted, it had a Humification Index (see glossary) of 0.27, indicating a well-humified (i.e., very mature) substrate. The product was virtually odorless, with the typical scent of soil.

Temperatures in the reactor quickly approached 131°F (55°C) and thermophilic conditions above 95°F (35°C) were maintained for approximately 80 days, despite the daily introduction of fresh liquid swine manure, which often increased mix moisture content beyond 75 percent. Oxygen levels started out quite high, ranging from 12.5 percent to 16.6 percent by volume after turning and aeration, but dropped to 0.9 percent shortly after turning ceased due to high levels of bacterial metabolic activity, even with adequate free air space. This limitation is believed to be due to high temperatures reducing the solubility of oxygen, high moisture levels in the mix that limited oxygen diffusion through the mix, and high metabolic consumption rates.

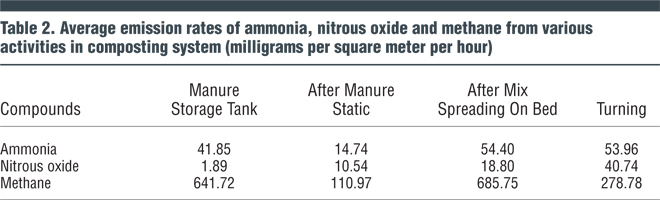

Emissions of ammonia, nitrous oxide, methane, hydrogen sulfide, and odors were closely monitored during the cycle. Average emissions rates of these gases are shown in Table 2. Ammonia emissions are typically due to the degradation of amino acids and urea and occur at high temperatures and pH levels. Ammonia (NH3) levels were higher during manure spreading on the bed, and turning events, with peak ammonia emissions between Days 50 and 65. However, ammonia emissions were comparable to the emissions from the manure storage tank, and significantly lower when the trough was not agitated.

Nitrous oxide (N2O) emissions are normally associated with denitrification processes that reduce nitrate-nitrogen to atmospheric nitrogen. N2O emissions peaked at Day 74 and, like ammonia, were higher after spreading and turning events. Methane emissions were detected, mainly after spreading, primarily due to the long storage periods when swine manure was held in the storage tank; the emissivity during turning and at static conditions, in fact, was significantly lower than emissions from the storage itself. Virtually no hydrogen sulfide emissions were detected (all less than 0.2 parts per million by volume (ppmv)). Odor emissions, measured by dynamic olfactometry, were charted at 30 Odor Units (OU)/m33 during turning.

Nitrogen Cycling

Researchers performed a nitrogen balance on the monitored composting cycle, calculating a total input of 20.93 tons (18.99 mt) of nitrogen in the feedstocks, a total nitrogen content in the finished compost of 2.97 tons (2.70 mt or 14.2%), and gaseous emissions losses in ammonia of 0.17 tons (9.16 mt or 0.9%) and in nitrous oxide of 0.033 tons (0.03 mt or 0.2%). This left 17.74 tons unaccounted for. By percentage, 14.19 percent of the input nitrogen remained in the compost, 1.05 percent and 0.18 percent were emitted as NH3 and N20 respectively, while the remaining nitrogen (84.76% of input N) represented unaccounted losses, which were considered to be emissions of nitrogen gas (N2), the product of the denitrification processes. Direct measurement of N2, the main component of air, is challenging, especially at full scale, so the research team turned to molecular biological analysis to verify that the unaccounted nitrogen losses were due to nitrification and denitrification (see glossary).

Historically, nitrification/denitrification has been considered a marginal process in composting and nitrogen loss was considered to be due primarily to ammonia emissions. Considering the limited emissions of ammonia and N2O, the unaccounted nitrogen losses at the swine manure composting facility at Bosco Chiesanuova were thought to be due to nitrification/denitrification caused by the high ammonia content in the swine manure, and by the alternating aerobic and low oxygen-anoxic conditions in the feedstock created by the daily liquid swine manure feed.

Molecular biology tools such as quantitative polymerase chain reaction (qPCR) offer simple and relatively inexpensive indirect evidence of the major microbiological processes involved in the nitrogen cycle within the composting process. The analyses conducted in this study were focused on the determination of four types of bacterial genes: bacterial nitrifiers (ammonia mono-oxygenase, or amoA-bacteria) and archeal nitrifiers (amoA-archea) which measure, respectively, nitrification by bacteria or by archaea (archaea are single-cell microbes similar to bacteria), and microbial denitrifying measurements using nitrous oxide reductase (nosZ). Presence of anaerobic ammonium oxidation (anammox) bacteria was determined using specific primer pairs within their ribosomal 16S rRNA genes. Anammox bacteria were identified in 1999, and are known to be able to directly convert nitrite and ammonium ions into diatomic nitrogen (N2) and water without the need for an organic carbon source for nitrification.

The bacterial amoA gene is normally found in nitrifying environments characterized by high levels of organic matter (such as wastewater), while the archaea amoA gene is normally found in less organically-rich environments, such as soils. The nosZ gene was considered indicative of the presence of denitrification. These genes are considered as useful biomarkers to assist current understanding of the dominant biological metabolism affecting nitrogen in composting.

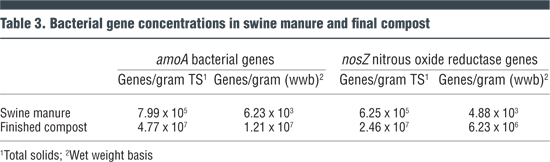

The research team did not find archaea amoA genes or Anammox bacteria, but did find elevated levels of amoA-bacterial genes and nosZ genes (Table 3), indicating that the elevated ammonia levels in the swine manure and the high thermophilic composting temperature did not inhibit nitrification, and that the presence of the nosZ gene, coupled with the low levels of N2O emissions observed, did confirm that denitrification to N2 took place in the composting system.

Optimization of nitrification and complete denitrification in composting is related to several factors. The aeration system was capable of obtaining temporary and localized aerated conditions required for the nitrification process, which is likely to occur in the aerated areas and on the surface area of the trough. The load of liquid swine manure on the absorbing/bulking agent was enough to achieve a moisture content ideal to obtain anoxic conditions necessary for denitrification. Characteristics of the input feedstocks were optimal in terms of total nitrogen and ammonium concentrations.

In addition to this work at Bosco Chiesanuova, similar results (in terms of mass reduction, unaccounted nitrogen losses with low emissions of NH3 and N2O) were obtained by monitoring other plants using the same technology to treat manures and digestates. This technology may have application to methods of managing liquid digestates from AD plants in areas where risk of nitrate contamination to groundwater is high and where regulatory requirements or proximity to sensitive receptors may require consideration of air emissions. Furthermore, there are several examples of successful marketing of compost from these plants, creating additional profit for farmers.

Alessandro Chiumenti is a University Researcher in the Department of Food, Environment and Animals at University of Udine, in Udine, Italy (Alessandro.chiumenti@uniud.it) and co-owner of Agri Planning Studio 3, Ponte San Nicolò, Italy (www.agriplanning.it). Craig Coker is a Senior Editor at BioCycle (ccoker@jgpress.com) and CEO of Coker Organics Recycling near Roanoke, VA (www.cokercompost.com). The research on which this article is based can be found at: Chiumenti, A. “Complete nitrification-denitrification of swine manure in a full-scale, non-conventional composting system”, Waste Management, 46 (2015) 577-587.