BioCycle September 2010, Vol. 51, No. 9, p. 46

BioCycle September 2010, Vol. 51, No. 9, p. 46

Solid waste management company in northeastern Italy operates two types of anaerobic digestion systems to process source separated organics.

Christian Garaffa

A pdf file of this article is also available.

SINCE the mid-1990s, food waste has been collected from households separately from yard trimmings in Italy. The door-to-door collection method allows for high capture and low contamination rates. In recent years, some of these programs have implemented anaerobic digestion (AD) as an initial processing stage, producing biogas from the organics and then composting the digestate.

This article focuses on the case study of ETRA S.p.A., an Italian public company that manages the integrated water and municipal solid waste collection and treatment service in an area of approximately 800 square miles in the northeastern region of Veneto. As of 2009, ETRA serves 63 municipalities with a population of 520,000 and collects 100,000 metric tons (110,000 tons) of organic waste annually.

Within the boundaries of this territory, organic waste is in a closed loop system, treated in a composting facility and two different AD facilities operated by ETRA – a dry continuous flow system in Bassano del Grappa (Vicenza) and a wet two-stage system in Camposampiero (Padova). ETRA is constantly pursuing maximum recovery with minimal contaminants through the continuous monitoring of the collected feedstocks, extensive information campaigns and promotion of the use of compostable bags for collecting organic waste.

COLLECTION TOOLS, “CLEAN ORGANICS”

The Italian system of intensive source separated organics (ISSO) involves frequent food waste collection, allowing for high capture of organics, and less frequent residual waste collection, helping to optimize the whole system. An important tool for ISSO is a 2-gallon vented kitchen pail used with compostable bags. Specific grades of Mater-Bi® compostable resin have a native starch content that allows for high water vapor transmission rates. This enables the transpiration of wet food waste, providing a weight and volume reduction resulting in less waste to be collected and treated. The water loss also reduces initial fermentation, meaning less generation of unpleasant odors, a more hygienic bin, and overall reduced “yuck” factor (see “Intensive Source Separated Organics,” April 2010).

However, according to Walter Giacetti, environmental manager at ETRA, SSO diversion programs on their own do not deliver the expected purity and diversion rates. “The roll out of any residential program must be supported by extensive information campaigns and tools which encourage participation,” he says. “We own and operate the facilities where this material is treated so not only do we want to reduce the environmental impacts, we have a vested interest in optimizing all parts of the system in order to minimize processing and [contamination] disposal costs.”

ETRA constantly monitors the quality of collected materials to maintain optimum performance and allow for a timely response to problems should they arise. Monitoring includes waste analyses, looking in particular at the total level of contaminants in the collected materials.

Throughout the years, ETRA has been managing an increasing number of municipal programs. While some municipalities didn’t always require compostable bags, others have had this requirement since the creation of the first organics collection programs in 1996. However, waste analyses showed that about 15 percent of families were still using conventional polyethylene shopping bags for collecting their kitchen scraps, probably because they were less expensive and more readily available. The data were further confirmed by waste analyses at ETRA treatment facilities, which showed a worse quality compared to the previous year.

To address the declining quality, an extensive campaign – “Umido Pulito” or “Clean Organics” – was organized between April and May 2008. The campaign (Figure 1) was aimed at improving the quality of food waste collected by empowering citizens and therefore facilitating the process of treatment and recycling.

Originally “Clean Organics” was implemented in 38 of the 63 municipalities that ETRA serves and covered 71 percent of the 520,000 inhabitants. The campaign is still ongoing with more municipalities joining. By the end of 2010, all municipalities in ETRA’s service area will have received the campaign and monitoring program.

The campaign was partly funded by ETRA, and partly by the municipalities themselves, which included a proportion of total costs in the yearly financial plan. The campaign also had the support of the Italian Composting Consortium.

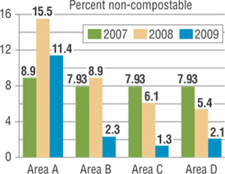

Bassano del Grappa, one of the first 38 municipalities involved in the initial phase of the “Clean Organics” campaign, has about 44,000 inhabitants and collects over 4,000 tons/year of organics. Its case is emblematic of how it was possible to reduce an average rate of about 8 percent contamination through information and promotion of compostable bags. The data in Figure 2 show how in 2009, after the communication campaign, implementation of a proper monitoring system and involvement of local businesses in promoting use of certified compostable bags, contamination dropped to less than 2.5 percent, resulting in avoided disposal of at least 200 metric tons of waste. The economic savings for the city of Bassano were about €30,000 (about $38,500).

Areas B, C, D (Figure 2) have curbside collection and showed the best results, while the historic downtown area (A) results are less striking because of the use of centralized road containers (the historic downtown accounts for about 10 percent of all kitchen organics collected). Road containers commonly achieve lower capture rates and tend to have higher contamination rates because of the lack of a direct link between householder and collection bin. Nevertheless, in some specific situations due to space and logistical constraints, this option can be preferred to curbside bins.

BASSANO DEL GRAPPA DIGESTER

Opened in mid-2003, ETRA’s AD facility in Bassano del Grappa treats separately collected residential food wastes using a Valorga dry continuous flow process. The resulting digestate is composted with yard trimmings and minor amounts of biosolids. The facility consists of preprocessing; three continuous flow cylindrical digester reactors with a total volume of 7,200m3; a composting plant for the digestate; a maturation pad; biogas clean up (methane and carbon dioxide); three CHP engines (powered with the biogas); and a dedicated sewer taking liquid from the dewatering process to a local treatment facility.

The Bassano plant was originally designed for treatment of MSW. However, the later introduction of the curbside collection of dry recyclables caused a significant change in the composition of the MSW, leading to higher sedimentation rates that clogged the digesters. This prompted a change to process just source separated food waste in the digesters.

Food waste entering the facility is placed in a bag splitter and then passed through a disc screen and magnetic separator. The overs from screening are sent for disposal in landfill or incineration with energy recovery. The larger pieces of compostable bags are captured in the overs; the smaller ones pass through the screen and enter the digester. ETRA is planning to introduce a mechanical-biological treatment (MBT) step prior to sending the overs to disposal in order to have a further reduction of weight and disposal cost.

Organic materials are steam-heated to reach the desired temperature (the walls of the digester are insulated but do not have any heating mechanisms) and loaded directly into three cylindrical digesters, each with a gross capacity of 2,400 m3. Solids content of feedstock entering the digester is 29 to 33 percent. The average retention time is 35 days.

After dewatering, digestate is mixed with structural woody material and biosolids before a two-stage composting process. The first phase is conducted in a closed warehouse, using 18 windrows with forced aeration. These are turned regularly for 18 to 30 days and then pass via conveyor belt to the refining process to remove any remaining contaminants. The compost is further matured for up to three months, with a total time to process each batch (AD plus aerobic composting) of never less than 90 days and often more than four to five months. This produces high-quality compost (after screening to 10 mm) used as fertilizer in agriculture. Air drawn from all parts of the premises is cleaned by an acid wash and then routed to a 1,000 m2 biofilter.

About 50 percent of all the contaminants removed from Bassano are generated during the refining step of the composted digestate. Increased use of compostable bags is a benefit in terms of reducing the plastic portion of the residues. The bits of compostable bags that enter the digester start degrading at this point and are completely degraded during the postcomposting stage.

CAMPOSAMPIERO DIGESTION PLANT

The Camposampiero facility opened in mid-2005, treating separately collected municipal organic wastes, animal manure and biosolids. The integrated biotreatment center consists of a reception hall and pretreatment facility; an area for reception and pretreatment of liquid waste; an anaerobic digester; and a treatment plant for wastewater. This plant utilizes a two-phase wet digestion process patented by Linde-KCA-Dresden GmbH that operates with low solids content under thermophilic conditions.

Source separated food waste is loaded into a bag opener with a front end loader, passed through a grinder and magnetic separator and then goes into a hopper. The shredded and cleaned waste enters the hydropulper, which after dilution with water or industrial leachate, blends the putrescible materials and, by sedimentation, separates out the heavy solids (bones and shells, spoons or any residual metal plugs, etc.). The liquid is discharged from the pulper into a drum screen that allows the separation of the pulp from plastics and other large fragments, which are washed and then pressed to remove excess water. The compostable bags are removed via the drum screen as well. ETRA is also planning to add an MBT step at this facility to treat the residues because of the high content of wet organic materials. The bags would biodegrade during the MBT stage.

Screened overs (washed and pressed) and the settling solids separated in the pulper (and partly also in two traps in the sieve) are sent to disposal. The pulped organics fraction enters the hydrolysis tank where it remains for just over a day before being fed into the anaerobic digester.

The liquid waste stream consisting of animal manure is subject to screening and grit removal, then placed in storage tanks and fed to the digester. Biosolids are thickened and placed in storage tanks or the hydrolysis tank, prior to loading into the digester.

The digester has a capacity of 3,300 m3 of which 3,000 are occupied by the liquid fraction. Mixing is ensured by recirculation of biogas (gas lift) together with the input and output flows of the liquids. Temperature is maintained between 53° and 55°C by external heat exchanger tube bundles that use heat emitted from diesel engines and heat recovered from the output gases.

Biogas passes through a gravel filter and is recycled or stored in the double skin 2,600 m3 gas tank at a pressure of 20 to 25 mbar. The plant was opened in 2006 and since 2007, the production of electricity has been constant leading to the generation of high levels of revenue.

Average retention time in the digesters is about 22 days, after which the digestate is dried by centrifugation with the addition of polyelectrolyte. The solid fraction is transferred to composting plants for stabilization prior to spreading in agriculture whereas the liquid is treated internally.

HANDLING COLLECTION BAGS

The systems used to handle bags of organic waste collected from households are extremely important. This involves both pre and post treatment steps to ensure operations run smoothly and produce a quality compost for agriculture.

Pretreatment consists of a range of operations that prepare a substrate for the biological process and depend on whether a dry or wet process is used. For dry processes, pretreatment does not require additional dilution, whereas for wet processes the selection phase typically involves the substrate being mixed with water while simultaneously separating the light (plastics) and heavy (inert) fractions.

In both facilities described, preprocessing technologies tend to separate bags and organics before the biological process. Bags are torn open mechanically followed by particle size reduction (avoiding excessive grinding). Inert materials and plastics are then separated in order to reduce friction and potential blockages in the biological process. However, a significant portion of organics attached to the bags is lost during this stage. One major benefit of a system using compostable bags is that depending on the purity of the collected feedstock, they may enter the facility with less intensive separation, subsequently reducing the loss of organic material and reducing the amount of overs generated during the refining process and sent to disposal. Moreover, bags entering the facility have already started degradation, are wet and not so easy to be separated from the overall food waste mass, which has not been a detriment to the operation of either digester facility, and has helped reduce the final residue stream.

The choice of technology for post treatment varies depending on the market for the final product and the level of contamination present. In a system where compostable bags enter the AD facility, the efficiency of this screening is less critical because remaining fragments have degraded in the postdigestion composting phase. Overall, ETRA has found that its facilities need to keep a balance between the intensity of the pretreatment screening process and relative purity of the screened material that is then fed into the digester. In other words, the more intense the screening, the more energy is consumed and the greater the amount of residues produced.

And as noted earlier, these residues contain a significant amount of organics sticking to the noncompostable materials. This “drag effect” usually causes the weight of the overs to double, i.e. one metric ton of organics lost and disposed of per each metric ton of noncompostable materials separated during the screening process. Therefore, if the contamination of the input material is kept below 2 to 3 percent, it is possible to have a less intensive screening because the digester systems are able to cope with that contamination level.

To keep impurities in the collected residential organic fraction well below 5 percent in ETRA’s service area, an appropriate monitoring system has been implemented along with an extensive information and awareness campaign. Local retailers also have been engaged in providing certified compostable bags at discounted prices. Last but not least, trained collection crews perform quality control while collecting the organic waste and provide doorstep guidance and continuous information to the householders. The “Clean Organics” information and awareness campaign has significantly improved both the quality and quantity of residential organics collected and reduced the amount of residues generated at ETRA’s treatment facilities, resulting in an overall better environmental and economic performance.

Christian Garaffa is Marketing Manager for source separation and recycling at Novamont SpA, producers of compostable polymers (christian.garaffa@novamont.com).

September 21, 2010 | General